Plastic Pipe Production Line

Introduction of plastic bellows production line

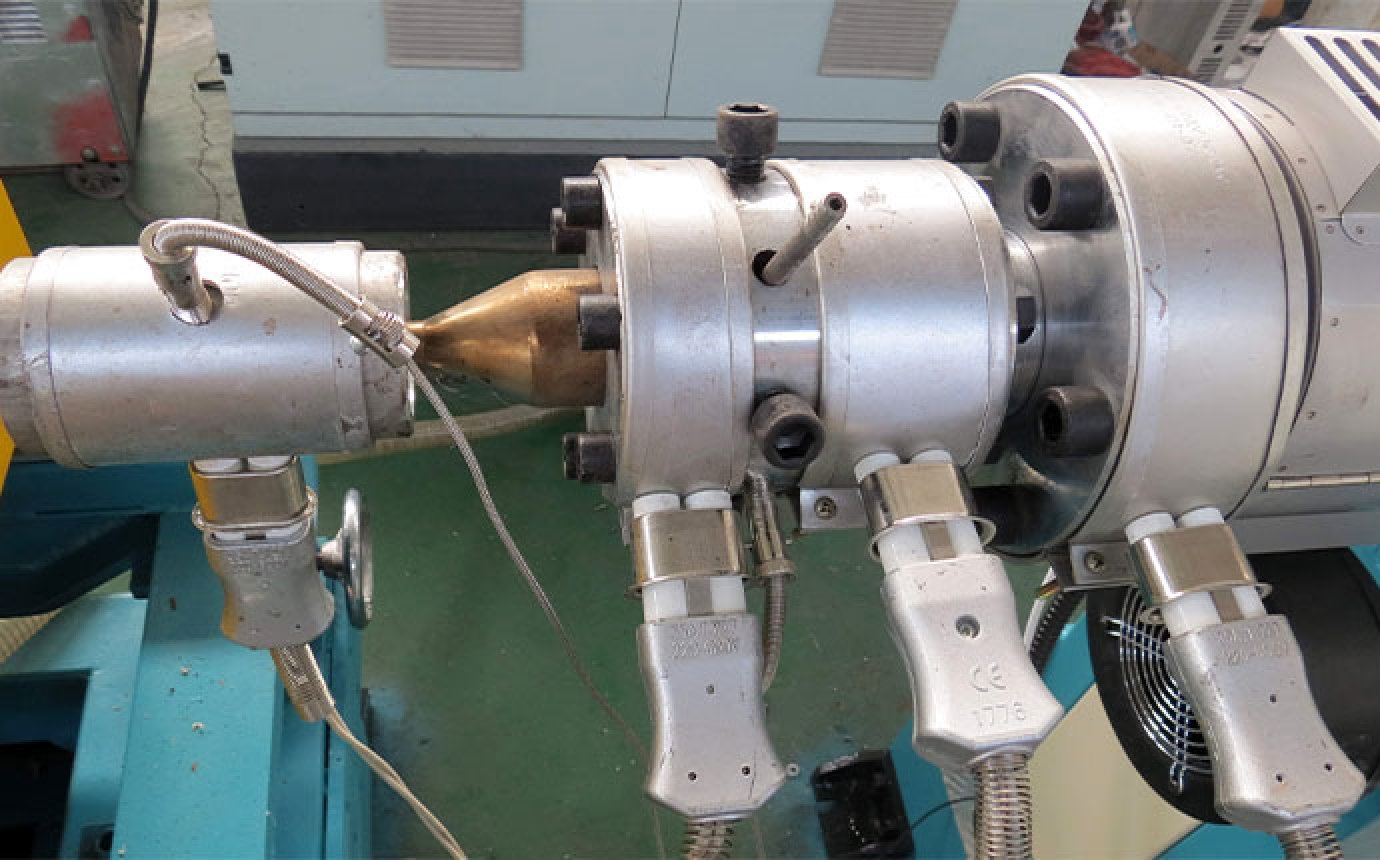

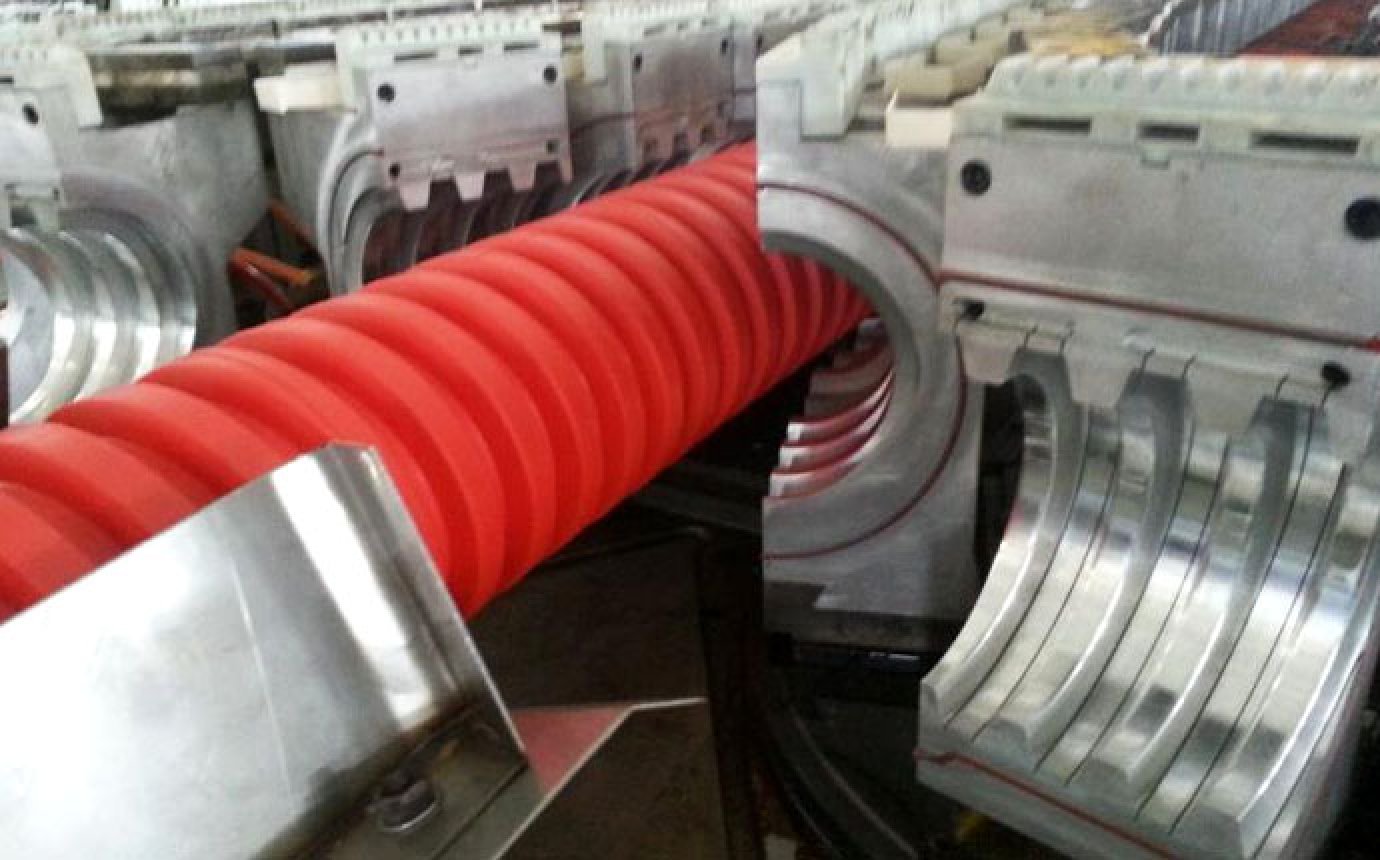

Plastic bellows production line can continuously produce PP,PE,PA ,EVA and other different materials of bellows .single/double wall corrugared pipe production line is mainly composed of:single screw or double screw extruder,nose and mold molding machine ,spray tank,cutting machine ,winding machine or stacking platform.

The forming machine adopts closed molding module chain,open design,module and mold frame accurately cooperate,each pair of molding module ,the dovetail slot and the module,the dovetail slot adopts accurate positioning ,mechanical locking ,and convenient replacement of specifications.

The forward and backward moving device of the forming machine adopts double linear rail guide device to improve the operation accuracy ,and the mobile motor is installed above ,which provides great convenience for the future equipment maintenance and motor maintenance.

Inquire Now

Add to Inquiry Basket

Plastic Bellows Production Line

Automated Manufacturing System for High-Quality Corrugated Pipes & Bellows

Product Overview

The Plastic Bellows Production Line is a state-of-the-art, fully integrated system engineered to produce durable, flexible plastic corrugated pipes and bellows for automotive, construction, agriculture, and electrical industries. Utilizing advanced extrusion, vacuum calibration, and servo-controlled forming technologies, this line ensures precision manufacturing of single-wall or double-wall bellows with consistent wall thickness and superior mechanical performance.

Key Features & Technical Highlights

High-Speed Continuous Production

Automated extrusion, corrugation molding, cooling, and cutting processes achieve speeds of 10–25 meters/minute, maximizing output efficiency.

Modular design supports 24/7 operation with minimal downtime.

Precision Corrugation Technology

Servo-driven vacuum forming system creates uniform corrugation profiles (round, spiral, or custom shapes) with wall thickness accuracy of ±0.1mm.

Adjustable mold sets accommodate diameters from Φ10mm to Φ800mm.

Multi-Material Compatibility

Processes HDPE, PP, PVC, PA (nylon), and recycled plastics.

Optional co-extrusion module for multi-layer or reinforced bellows (e.g., embedded steel wire).

Smart Control System

PLC + touchscreen HMI for real-time monitoring of temperature, speed, and pressure.

Auto-diagnostic alerts for mold alignment, material feed, and cooling anomalies.

Energy Efficiency

Variable frequency drives (VFDs) reduce power consumption by 25% vs. conventional systems.

Closed-loop water cooling for rapid heat dissipation and material stability.

Technical Specifications

Power Requirements: 380V/50Hz (customizable to 220V/60Hz)

Screw Diameter: 45–120mm (based on material and output)

Heating Zones: 4–6 zones with PID temperature control (±1°C)

Cooling System: High-pressure vacuum water tank + air cooling

Cutting Precision: Laser or servo cutter with ±0.5mm tolerance

Advantages for Buyers

Cost-Effective Production: Reduced material waste (<2%) and lower labor costs via full automation.

Versatility: Quick mold changes enable small-batch customization for niche markets.

Durability: Produces bellows with high UV resistance, impact strength, and temperature tolerance (-40°C to +120°C).

Easy Maintenance: Tool-free access to critical components for rapid cleaning and adjustments.

Applications

Automotive wiring harness protection and exhaust systems

Cable conduits for telecom and electrical infrastructure

Drainage and irrigation corrugated pipes

Ventilation ducts and pneumatic tubing

Certifications & Standards

CE, ISO 9001, and RoHS compliant.

Meets ISO 10380 (corrugated flexible metallic hoses), ASTM F2435 (plastic piping systems), and industry-specific certifications.

Support Services

On-site installation, operator training, and process optimization.

Lifetime technical consultation and spare parts supply.

Custom solutions for reinforced bellows, anti-static coatings, or color-masterbatch integration.

Media Contact: https://www.hst-plasticmachinery.com/hiadmin.php?c=index

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.comSales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China