Plastic Pipe Production Line

HDPE inner rib reinforced winding tube production line can produce DN200-2000 inner rib reinforced spiral bellows,inner rib tube with high density polyethylene [HDPE]as raw material ,has the characteristics of large surface area,inner rib structure,tube soil with compression ,improve the stability of the ring stiffness.

Inquire Now

Add to Inquiry Basket

Double-Wall Corrugated Pipe Production Line

Advanced System for High-Strength Corrugated Drainage & Cable Conduit Pipes

Product Overview

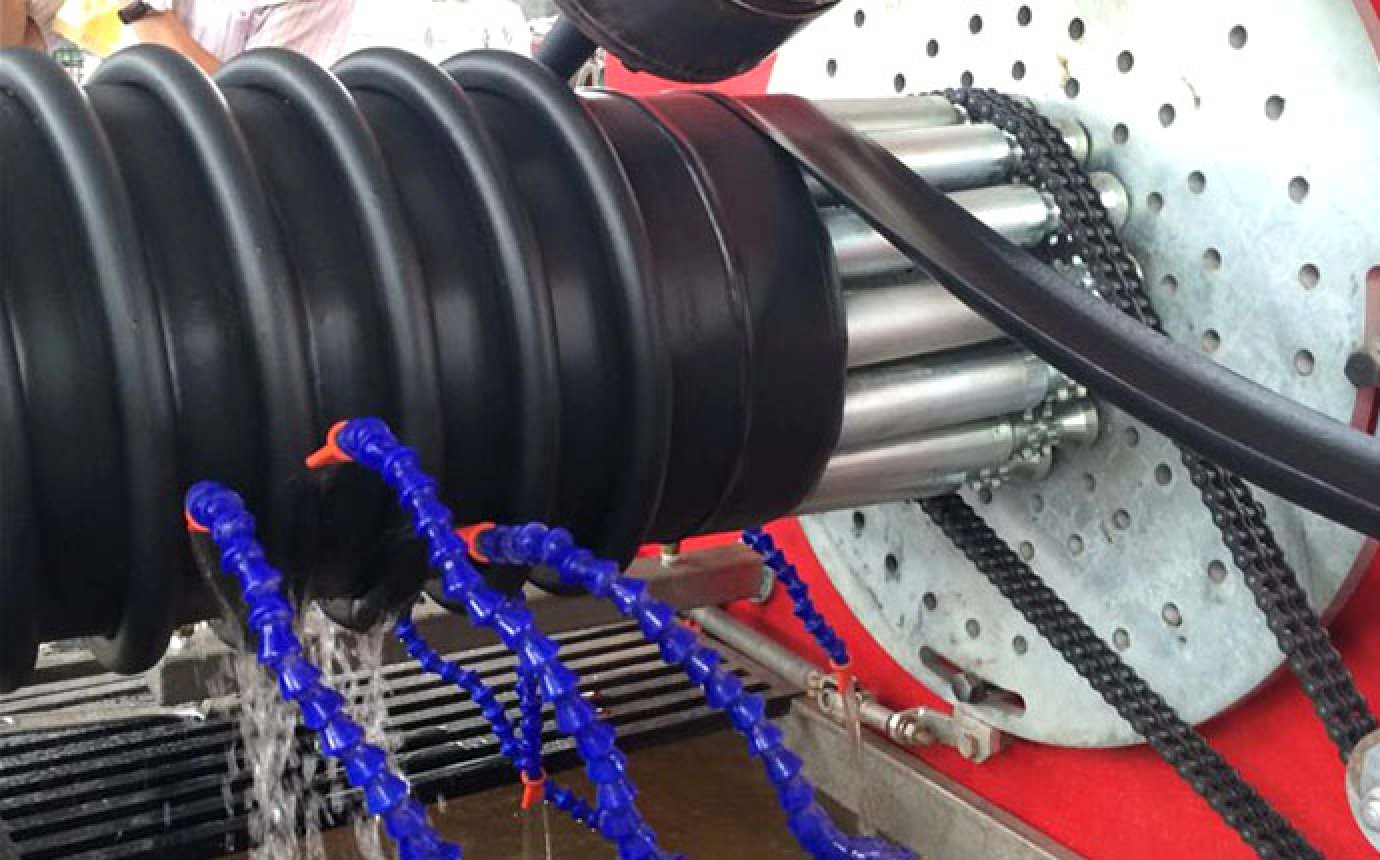

The Double-Wall Corrugated Pipe Production Line is an automated, high-efficiency solution for manufacturing dual-layer pipes with a smooth inner wall and corrugated outer structure. Ideal for drainage, cable protection, and agricultural applications, this line integrates co-extrusion, vacuum cooling, and servo-controlled molding to produce pipes with superior ring stiffness, impact resistance, and hydraulic efficiency.

Key Features

Dual-Layer Co-Extrusion: Simultaneously extrudes inner smooth HDPE/PP layer and outer corrugated layer for optimal flow and structural strength.

High-Speed Output: Achieves production speeds of 8–20 meters/minute (adjustable based on pipe diameter).

Precision Corrugation: Servo-driven vacuum molds create uniform outer ribs (round, spiral, or helical designs) with wall thickness accuracy of ±0.2mm.

Smart Automation: PLC + HMI interface controls extrusion temperatures, vacuum pressure, and cooling parameters in real time.

Energy-Saving Design: Variable frequency drives (VFDs) and heat recovery systems cut energy use by 30%.

Technical Specifications

Pipe Diameter: 50mm–1200mm

Material: HDPE, PP, or recycled plastics

Wall Thickness: 1.5mm–8mm (inner) / 2mm–12mm (outer)

Power: 380V/50Hz (customizable voltage/frequency)

Output: 500–2,500 kg/day

Advantages

✅ High Durability: UV-stabilized materials and reinforced ribs withstand harsh environments.

✅ Cost Efficiency: Low material waste (<3%) and minimal downtime with quick mold changes.

✅ Versatility: Produces SN4–SN16 ring stiffness classes for underground/aboveground use.

✅ Eco-Friendly: Compatible with recycled plastics and RoHS-compliant additives.

Applications

Stormwater and sewer drainage systems

Telecom and electrical cable conduits

Agricultural subsurface irrigation and land reclamation

Industrial venting and culvert pipes

Certifications

CE, ISO 9001, and compliant with ASTM F2648 (corrugated HDPE pipe standards) and ISO 9969 (stiffness testing).

Support Services

Turnkey installation, operator training, and process optimization.

24/7 technical support and lifetime access to spare parts.

Custom solutions for anti-static, flame-retardant, or color-masterbatch integration.

Media Contact: https://www.hst-plasticmachinery.com/hiadmin.php?c=index

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.com

Sales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China