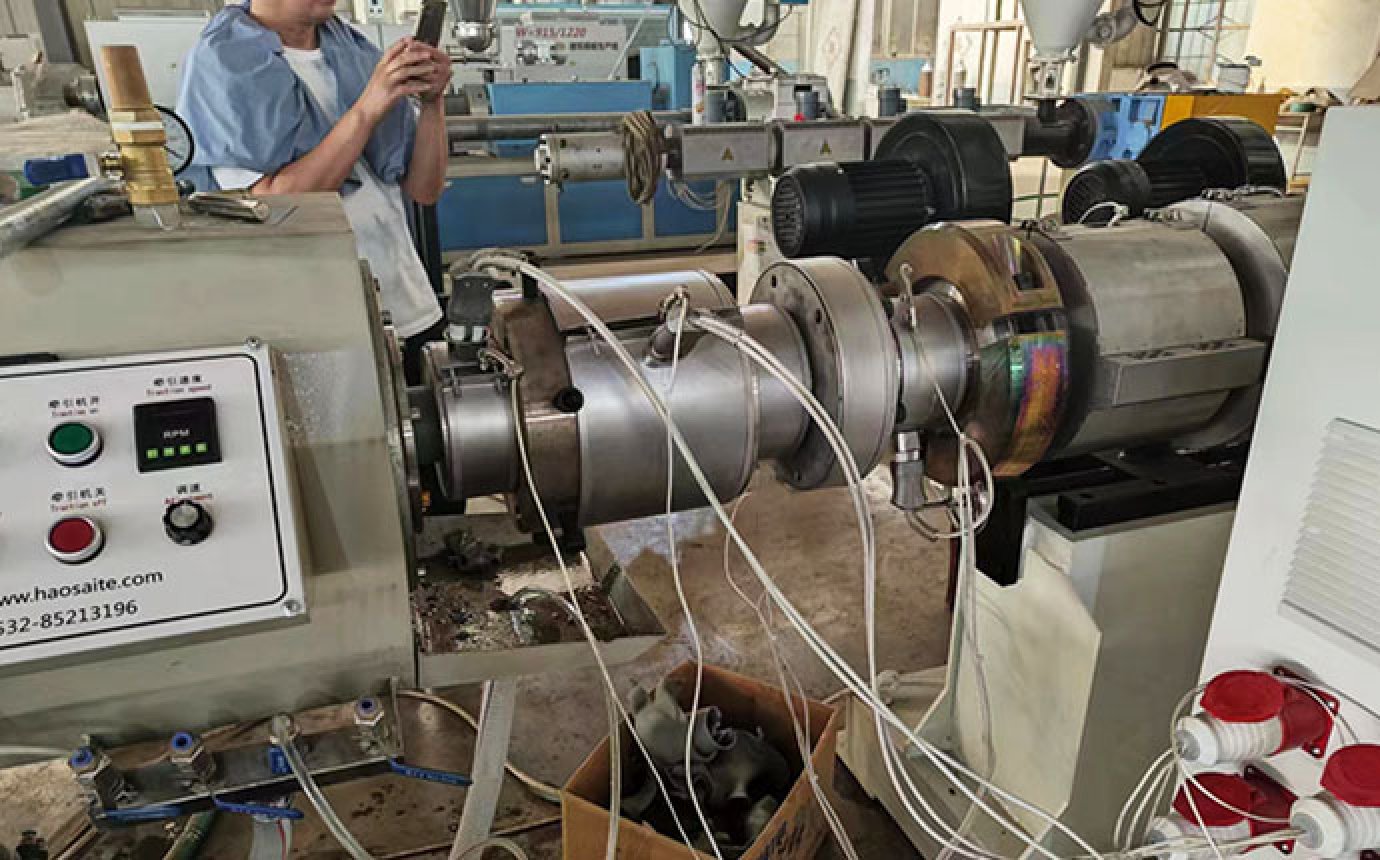

Plastic Pipe Production Line

PVC hard pipe production line is a kind of pipe production line ,simple operation ,high effciency and low production cost,the PVC pipe of is production line has the characteristics of high ring stiffness ,light quality ,convenient construction and other characteristics .

PVC pipe whether in municipal construction or irrigation and other aspects ,is a very wide use of a pipe . such as ,the municipal sewage discharge ,farmland irrigation ,tap water pipe .therefore ,the PVC hard pipe production line has been vigorously promoted in all countries .

Inquire Now

Add to Inquiry Basket

PVC hard pipe production line integrates ,traction ,cutting ,unloading ,and has the characteristics of high degree of automation ,good plasticization ,long life and so on.

PVC composition of the hard pipe production line :

Extruder part | ||||

Order | Specifications,names | Unit | quantity | Remarks |

1 | Stainless steel hopper +screw feeder | Set | 1 | |

2 | SJSZ80/156 conpered twin -screw extruder | Set | 1 | Frequency conversion feeding system |

3 | Mold and nose | Set | 1 | |

4 | Vacuum shaped water tank | set | 1 | stainless steel production |

5 | Traction engine | Set | 1 | |

6 | Cutting machine | Set | 1 | |

7 | Piling bin | set | 1 | |

8 | Laser price | Set | 1 | |

9 | Electrical control system | set | 1 | Siemens contactor |

10 | 300/600 mixing unit | Set | 1 | Frequency conversion energy saving |

PVC Pipe Production Line

Automated Manufacturing Solution for High-Quality PVC Pipes

Product Overview

The PVC Pipe Production Line is a fully integrated system designed to produce rigid and flexible PVC pipes for water supply, drainage, irrigation, and electrical conduits. Combining advanced extrusion, vacuum calibration, and cutting-edge automation, this line ensures high output efficiency, precise dimensional control, and compliance with global quality standards.

Key Features & SEO-Optimized Highlights

High-Speed Extrusion

Processes uPVC, CPVC, and PVC blends at speeds up to 15–35 meters/minute (adjustable).

Output capacity: 500–3,000 kg/day (varies by pipe diameter and thickness).

Precision Control

PLC + HMI interface for real-time monitoring of extrusion temperature, screw speed, and vacuum cooling.

Wall thickness tolerance: ±0.1mm; diameter range: Ø16mm–630mm.

Energy Efficiency

Servo-driven motors and optimized heating zones reduce energy consumption by 25%.

Closed-loop water cooling system minimizes waste.

Multi-Layer Capability

Optional co-extrusion module for foam-core or multi-layer pipes (e.g., anti-static, chemical-resistant).

Durability & Compliance

Produces pipes meeting ISO 4435 (buried drainage), ASTM D1785 (pressure pipes), and RoHS standards.

Technical Specifications

Power Supply: 380V/50Hz (customizable to regional standards)

Screw Diameter: 45–135mm (model-dependent)

Heating Zones: 5–8 zones with ±1°C accuracy

Cooling System: Vacuum tank + spray cooling

Cutting Length: 4–12 meters (programmable)

Advantages for Buyers

Low Operational Costs: Automated feeding, cutting, and stacking reduce labor needs.

Versatility: Produces solid-wall, spiral, or corrugated pipes in multiple colors.

Quick ROI: High uptime (>95%) and minimal material waste (<2%).

Global Certifications: CE, ISO 9001, and ISO 14001 compliant.

Media Contact: https://www.hst-plasticmachinery.com/hiadmin.php?c=index

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.com

Sales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China