Plastic Pipe Production Line

Inside the set patch type drip irrigation belt production line

The inner patch drip irrigation belt is an integrated drip irrigation pipe with flat shaped head set on the inner wall of the pipe belt ,which is widely used in the irrigation of field cash crops ,product features have :drip head and pipe belt integration ,easy to install and use ,low cost ,less investment .

Inquire Now

Add to Inquiry Basket

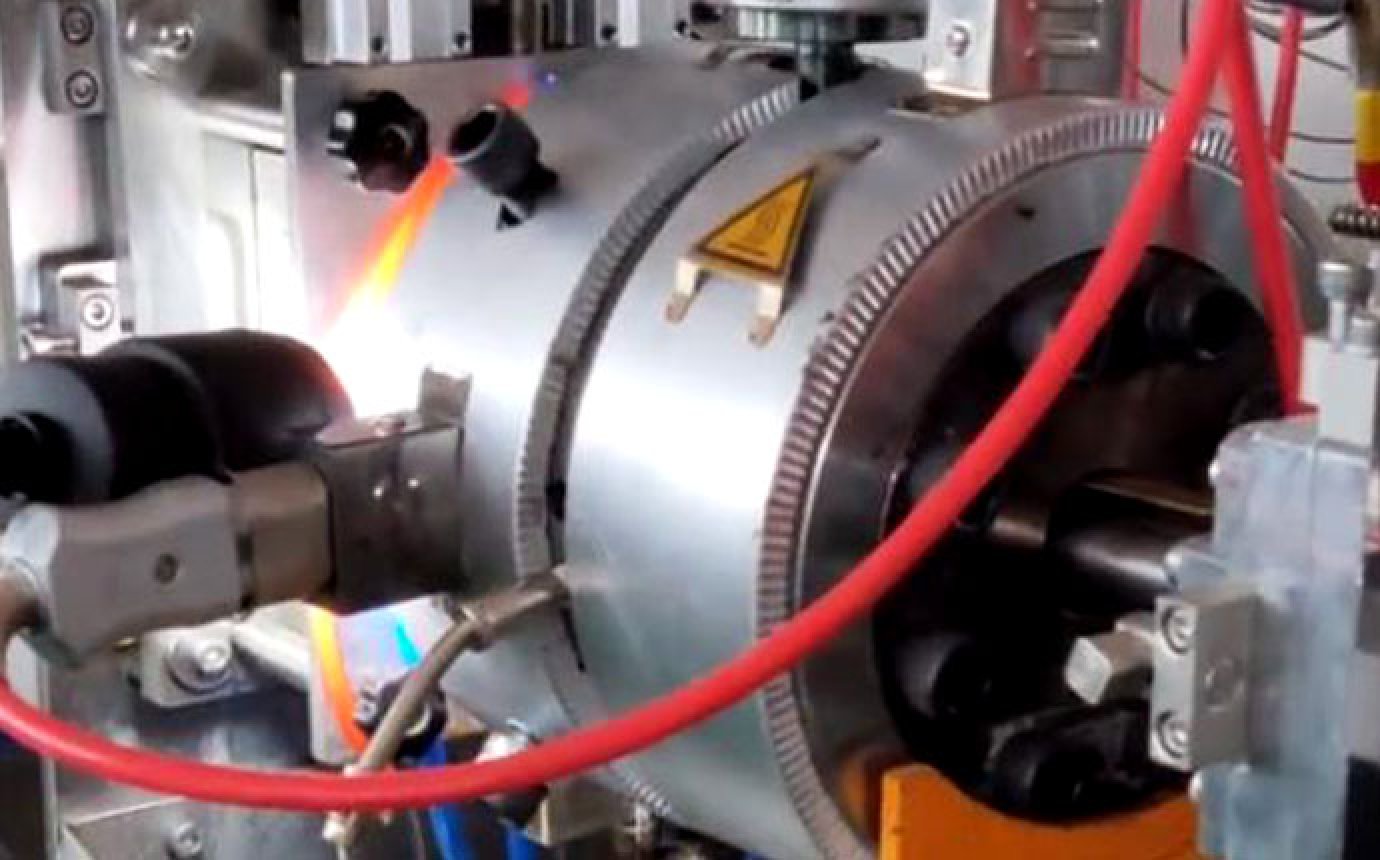

Production line detail

1 | Drop screen device |

2 | Drop head delivery device |

3 | Drop head storage device |

4 | Drop head bonding device |

5 | Extruder |

6 | Mold |

7 | Stainless steel vacuum setting box |

8 | Stainless steel cooling water sink |

9 | Belt tractor |

10 | Four-knife punching device |

11 | Duplex rolling machine |

12 | Cooling-water machine |

Inlaid Drip Irrigation Belt Production Line

Automated Manufacturing Solution for Precision Water-Saving Irrigation Systems

Product Overview

The Inlaid Drip Irrigation Belt Production Line is a high-efficiency system designed to produce flat inlaid drip tapes with integrated labyrinth channels. Ideal for agriculture, greenhouses, and landscaping, this line combines advanced extrusion, laser perforation, and cooling technologies to deliver uniform, clog-resistant irrigation belts for precise water and nutrient delivery.

Key Features

Integrated Labyrinth Channel Design: Embeds drip emitters directly into the belt during extrusion for consistent flow rates (1.0–3.0 L/h) and ±5% flow uniformity.

High-Speed Production: Achieves speeds of 80–150 meters/minute (adjustable) with LLDPE or recycled materials.

Laser Perforation: Precision laser drilling creates evenly spaced outlets (10–50 cm intervals) with ±0.1mm accuracy.

Automated Control: PLC + HMI interface monitors extrusion thickness, cooling, and winding tension in real time.

Energy-Saving: Servo-driven motors reduce power consumption by 25% vs. traditional systems.

Technical Specs

Belt Width: 16–50 mm

Thickness: 0.15–0.6 mm

Material: LLDPE, HDPE, or blended resins

Power: 380V/50Hz (customizable)

Output: 1,000–3,000 kg/day

Advantages

✅ 90% Water Efficiency: Reduces waste with pressure-compensated flow.

✅ Durability: UV-resistant additives extend lifespan to 5–8 seasons.

✅ Customizable: Adjustable emitter spacing, belt colors, and packaging (rolls/folded).

✅ Low Maintenance: Tool-free mold changes and auto-cleaning functions.

Applications

Row crops, vineyards, and orchards

Greenhouse hydroponics

Rooftop gardens and turf irrigation

Certifications

CE, ISO 9001, and compliant with ISO 9261 (agricultural irrigation standards).

Support

On-site installation, operator training, and lifetime technical support.

Custom solutions for anti-clogging additives or hybrid multilayer belts.

Media Contact: https://www.hst-plasticmachinery.com/hiadmin.php?c=index

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.com

Sales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China