Plastic Sheet Production Line

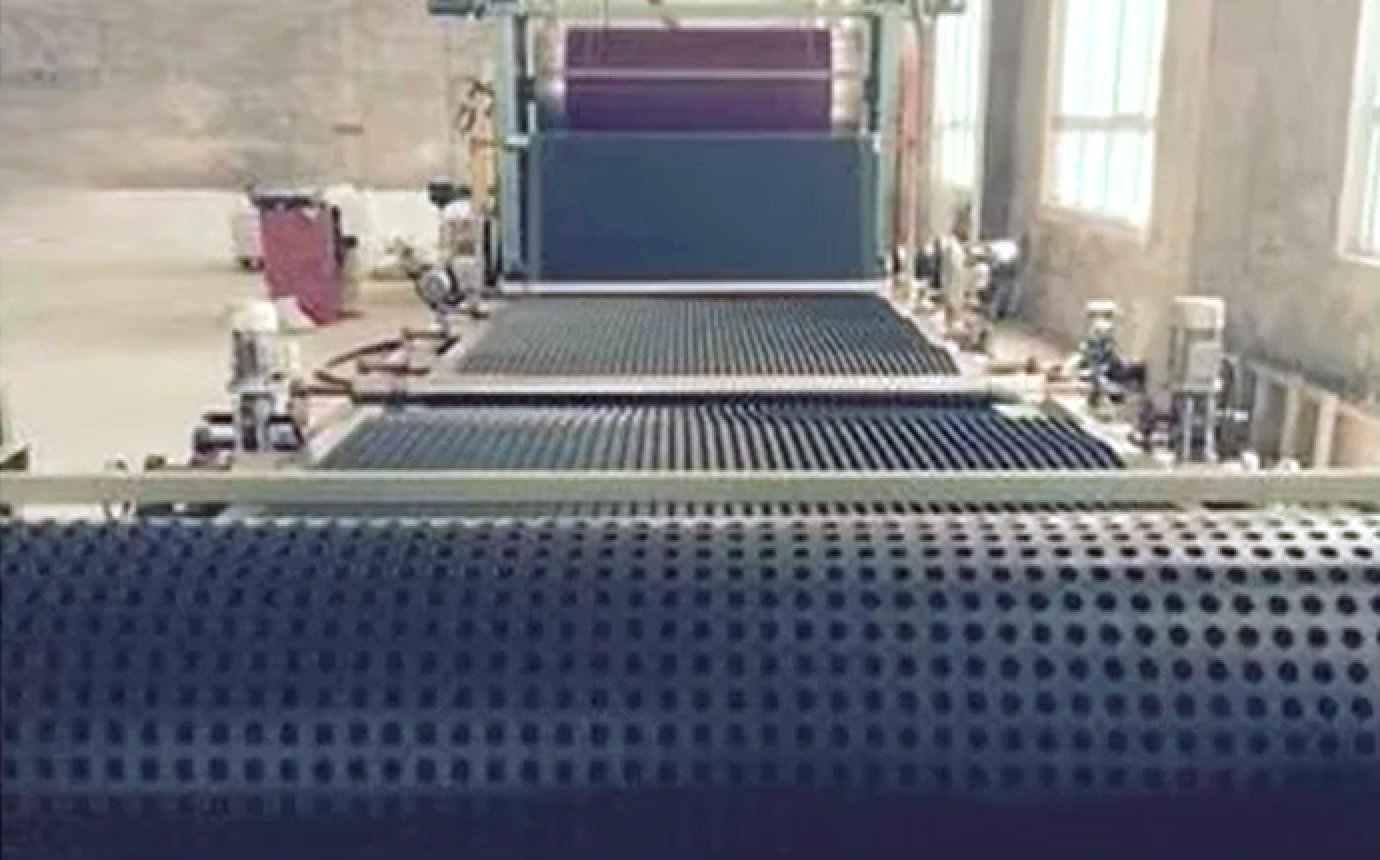

HDPE drainage board production line is used for the production of high strength waterproof ,drainage protection board ,the product has a concave and convex arrangement of hollows stud structure,can quickly hollow stud structure ,can quickly and effectively discharge rainwater.

Inquire Now

Add to Inquiry Basket

Product Name: HDPE Drainage Plate Production Line

Application: Designed for manufacturing high-performance HDPE (High-Density Polyethylene) drainage plates used in geotechnical engineering, landscaping, foundation drainage, and civil infrastructure projects.

Key Features

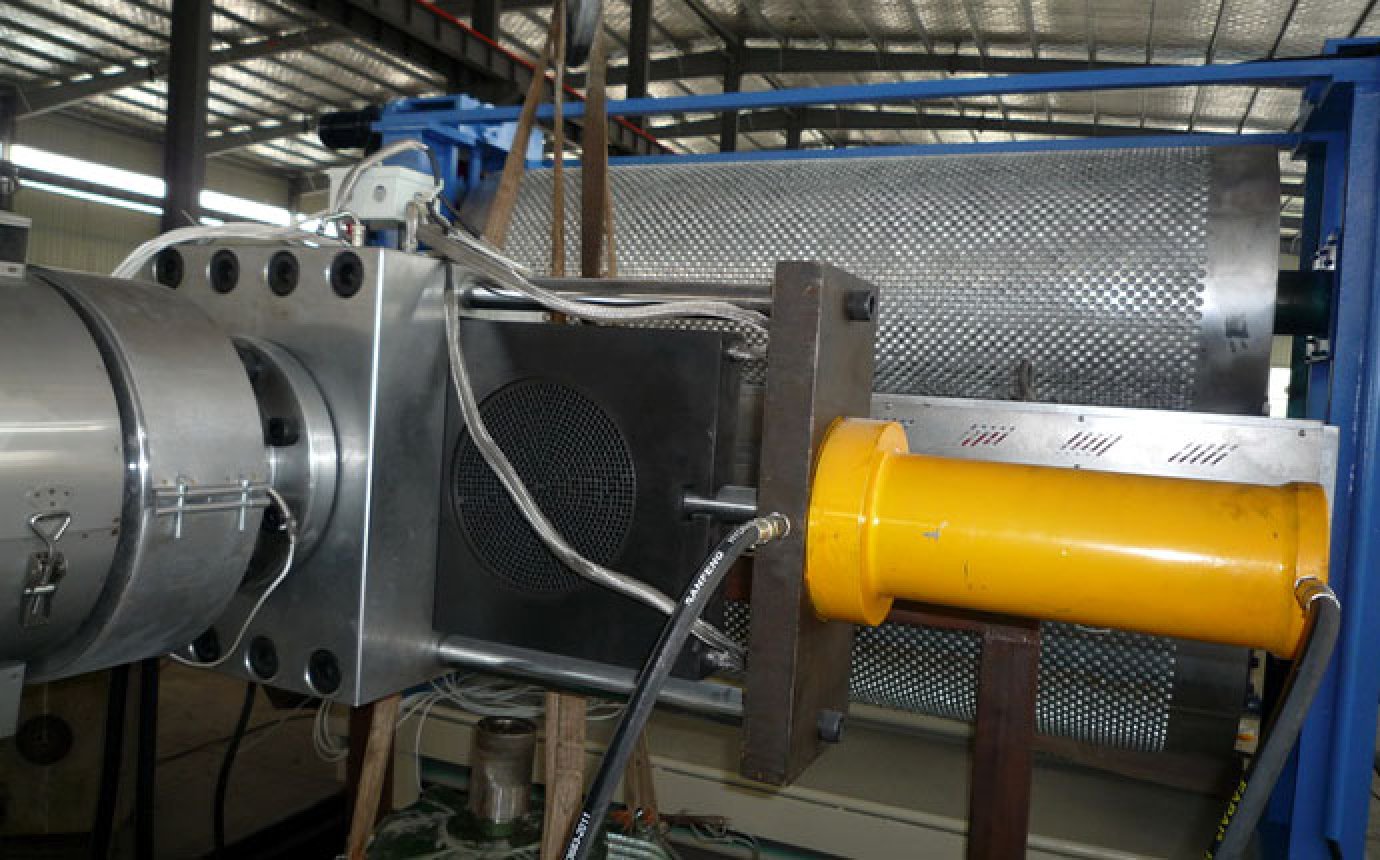

High-Strength Extrusion Technology

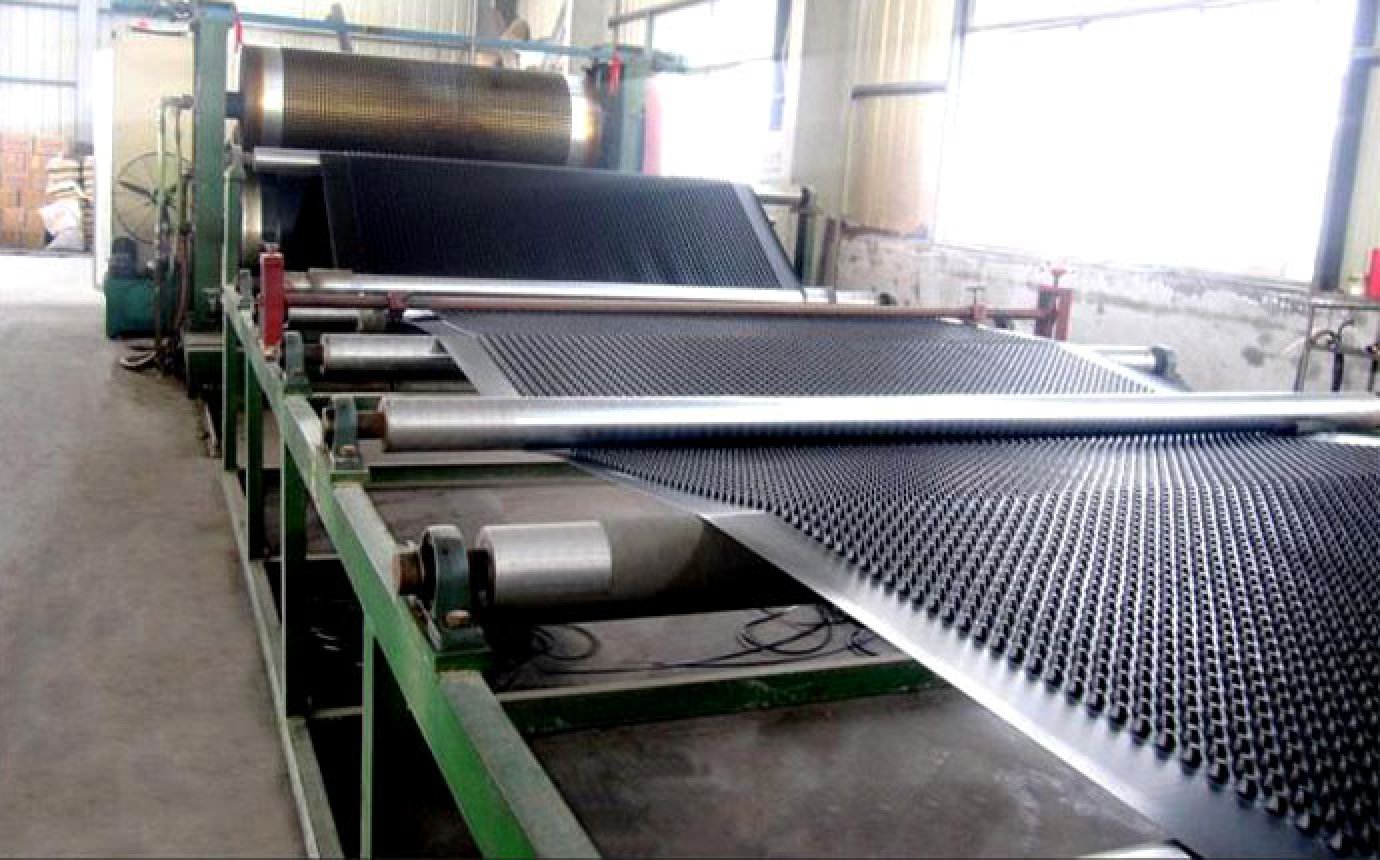

Produces durable HDPE drainage plates with uniform dimpled/studded surfaces for optimal water drainage, soil stabilization, and root barrier functions.

Adjustable thickness (10–25mm) and plate width (1–3m) to meet project-specific requirements.

Fully Automated Process

Integrated system: Raw material feeding → extrusion → embossing → cooling → cutting → stacking.

PLC-controlled operation ensures precision and consistency, with speeds up to 10–20 meters/minute.

Material Versatility

Compatible with virgin or recycled HDPE granules, UV-stabilized formulations, and anti-aging additives for extended outdoor durability.

Energy Efficiency

High-output twin-screw extruder with optimized thermal control reduces energy consumption by 15–25%.

Closed-loop water cooling system minimizes waste.

Customization Options

Surface patterns: Dimpled, studded, or hybrid designs for varying flow rates.

Optional perforations or geotextile laminating modules for advanced drainage solutions.

Technical Specifications

Output Capacity: 500–1,200㎡/day (depending on plate thickness)

Power: 120–250 kW

Production Speed: 10–20 m/min

Raw Material: HDPE granules (density ≥0.945g/cm³)

Automation: Fully automatic with touchscreen HMI.

Media Contact: https://www.hst-plasticmachinery.com

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

whatsapp/Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.comSales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China