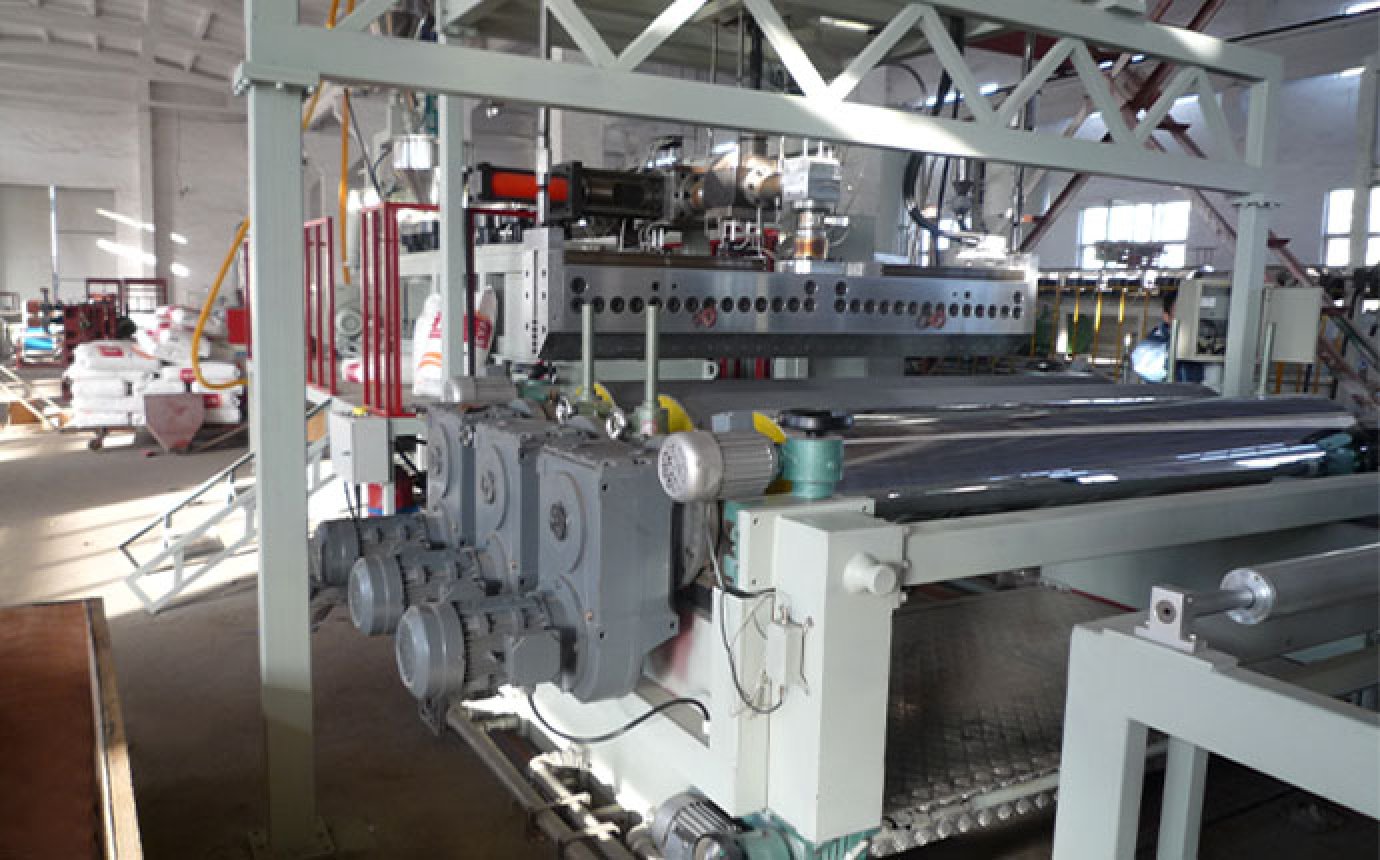

Plastic Sheet Production Line

Product Name: Plastic Sheet Extrusion Production Line

Application: Designed for manufacturing high-quality plastic sheets (PP, PVC, HDPE, etc.) used in packaging, construction, automotive interiors, and industrial applications.

Key Features

Versatile Material Compatibility: Processes PP, PVC, ABS, HDPE, and recycled plastics into sheets of varying thickness (0.2–15mm) and widths (up to 3m).

High Precision & Speed: Advanced extrusion technology ensures uniform thickness (±0.05mm) and smooth surfaces. Production speeds up to 15m/min.

Fully Automated: Integrated systems for material feeding, extrusion, calendering/cooling, cutting, and stacking.

Energy-Efficient Design: Optimized screw extruders and heat recovery systems reduce power consumption by 15–25%.

Customizable Output: Adjustable rollers and dies for glossy, matte, textured, or embossed finishes.

Inquire Now

Add to Inquiry Basket

Technical Specs

Power: 50–250 kW

Output Capacity: 300–1,000 kg/hour (varies by material and thickness)

Automation: PLC-controlled with touchscreen HMI.

Optional Add-Ons: UV stabilizers, anti-static modules, or multi-layer co-extrusion for enhanced performance.

Advantages

Durability: Produces sheets resistant to moisture, chemicals, and wear.

Cost-Effective: Lowers material waste and labor costs via automation.

Eco-Friendly: Supports recycled plastics and energy-saving operations.

Applications

Packaging trays, signage, automotive liners, greenhouse panels, and acoustic insulation.

Media Contact: https://www.hst-plasticmachinery.com

Name:Nancy Bao

Company Name:Qingdao Haosaite Plastic Machinery

whatsapp/Phone Number/Wechat:+8615854298193

Email Address:suji@haosaite.com

Sales6@haosaite.com

Website:Qingdao Haosaite Plastic Machinery

Arress:NO.398 B-9,Jiaozhou Road Jiaozhou Qingdao City,China